Mechanical Engineering student from the University of Texas at Austin. Epee Captain of UT Fencing. Founder of the Longhorn Design Lab

Outcome

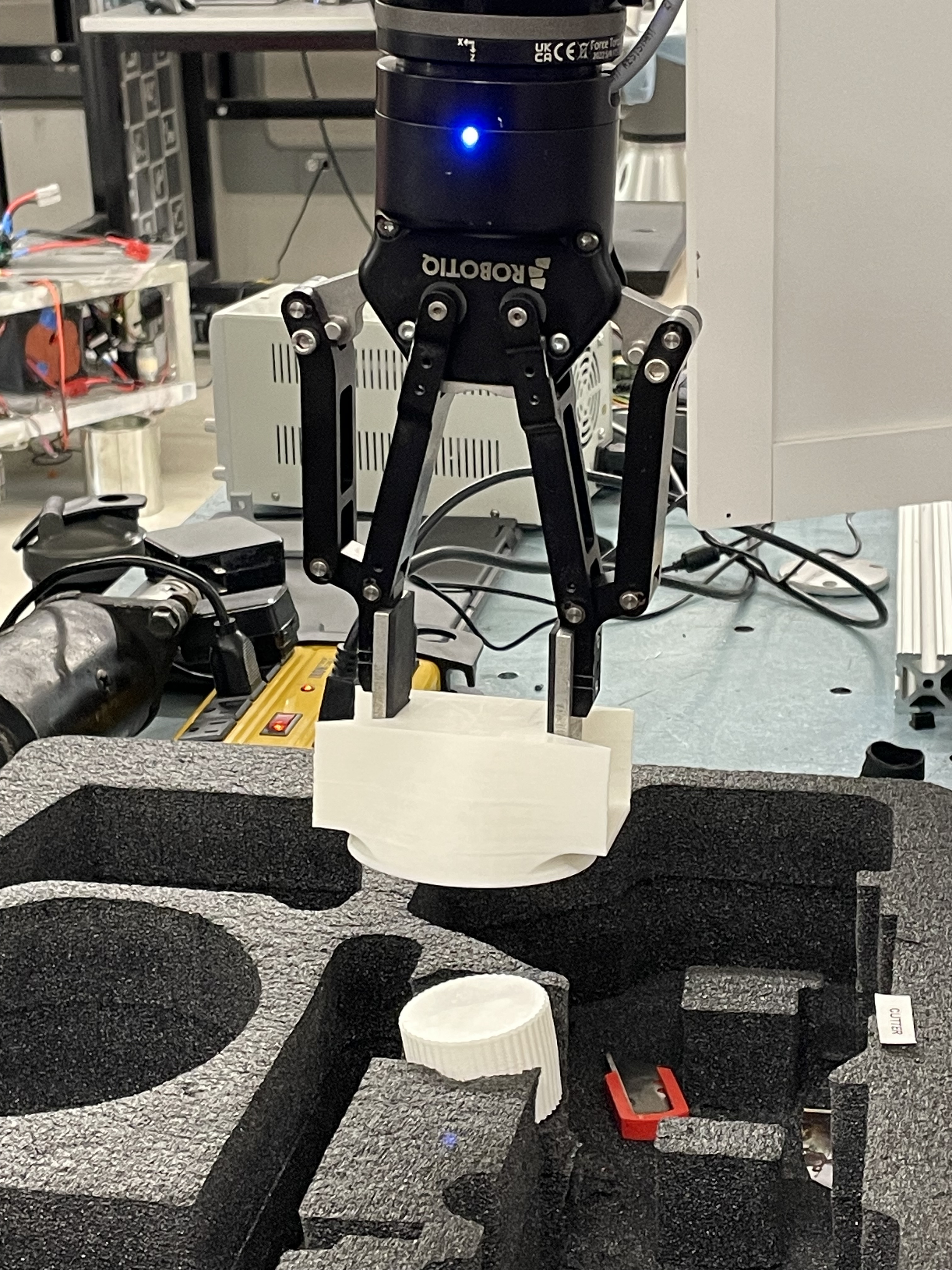

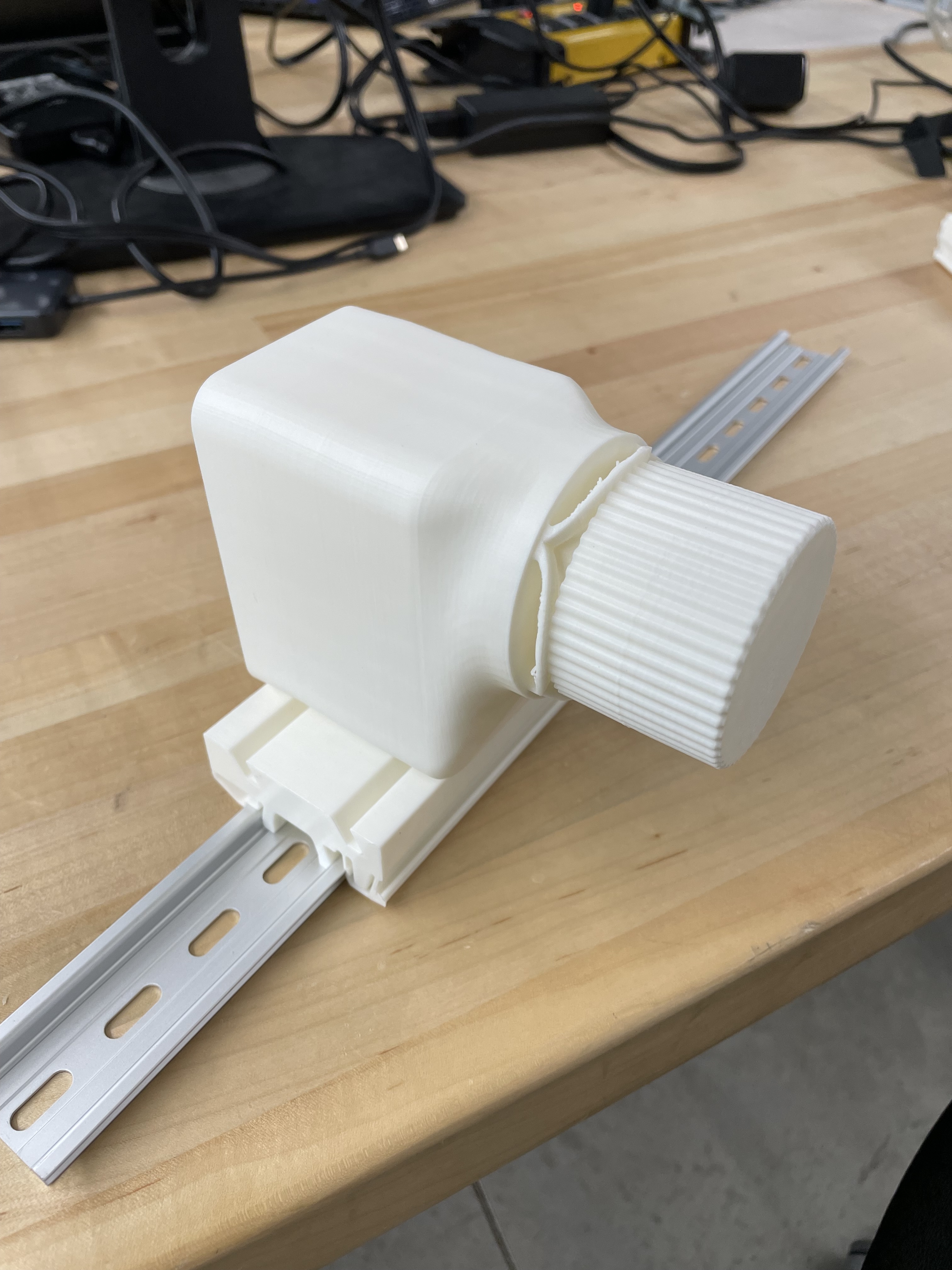

For my inaugural project with the Nuclear and Applied Robotics group at The University of Texas at Austin, I worked on a project for the U.S. Space Force. Our objective was to develop algorithms that would enable robotic arms, tasked with repairing complex satellite components, to effectively respond to force feedback when executing contact tasks. As part of the team, I was tasked with creating a prop that would simulate a complex force feedback-related task that our arm could interact with. I developed a 'pill bottle' mechanism, which provided a push-and-twist function that allowed us to test and demonstrate the capabilities of our algorithm.

Experience, Learning & Skills

This project taught me a lot about the importance of rapid prototyping, though not for the reasons I initially expected. A mechanism that complex takes only a few days to “crack.” However, by consistently producing prototypes throughout the design process, I was able to quickly put every new idea into the hands of a Research Engineer. This provided me with critical feedback early on and significantly reduced the overall design time.

I also gained valuable experience in project leadership. Despite being new to the lab, I was given considerable autonomy on this project, which allowed me to learn how to manage a project effectively from start to finish. These leadership skills proved most transferable to future projects I undertook in the lab. While the technical challenges varied wildly, my approach remained consistent.

Motivation

One of the most interesting challenges in robotics is leveraging force feedback from a force-torque sensor to achieve successful contact tasks.

Take writing on a white board for example. You and I know that we need to push with a certain amount of force to draw a solid line. We can instruct a robot to execute the same task by instructing it to push into a white board with a certain amount of force, say 10 N.

Now imagine the white board is on an unlocked set of wheels. If the white board begins to move as we apply pressure, we would pull back and stop.

However, when the robot attempts to write on the white board, it will think that it isn't applying enough force and will continue to apply force—hypothetically accelerating dangerously.

This is the problem our lab was asked to tackle in a project we did for the U.S. Space Force. Our goal was to develop algorithms that would allow robotic arms tasked with fixing complex satellite components to effectively respond to force feedback. Force controllers aren't new, but our novel solution implemented an impedance model.

Technical Details

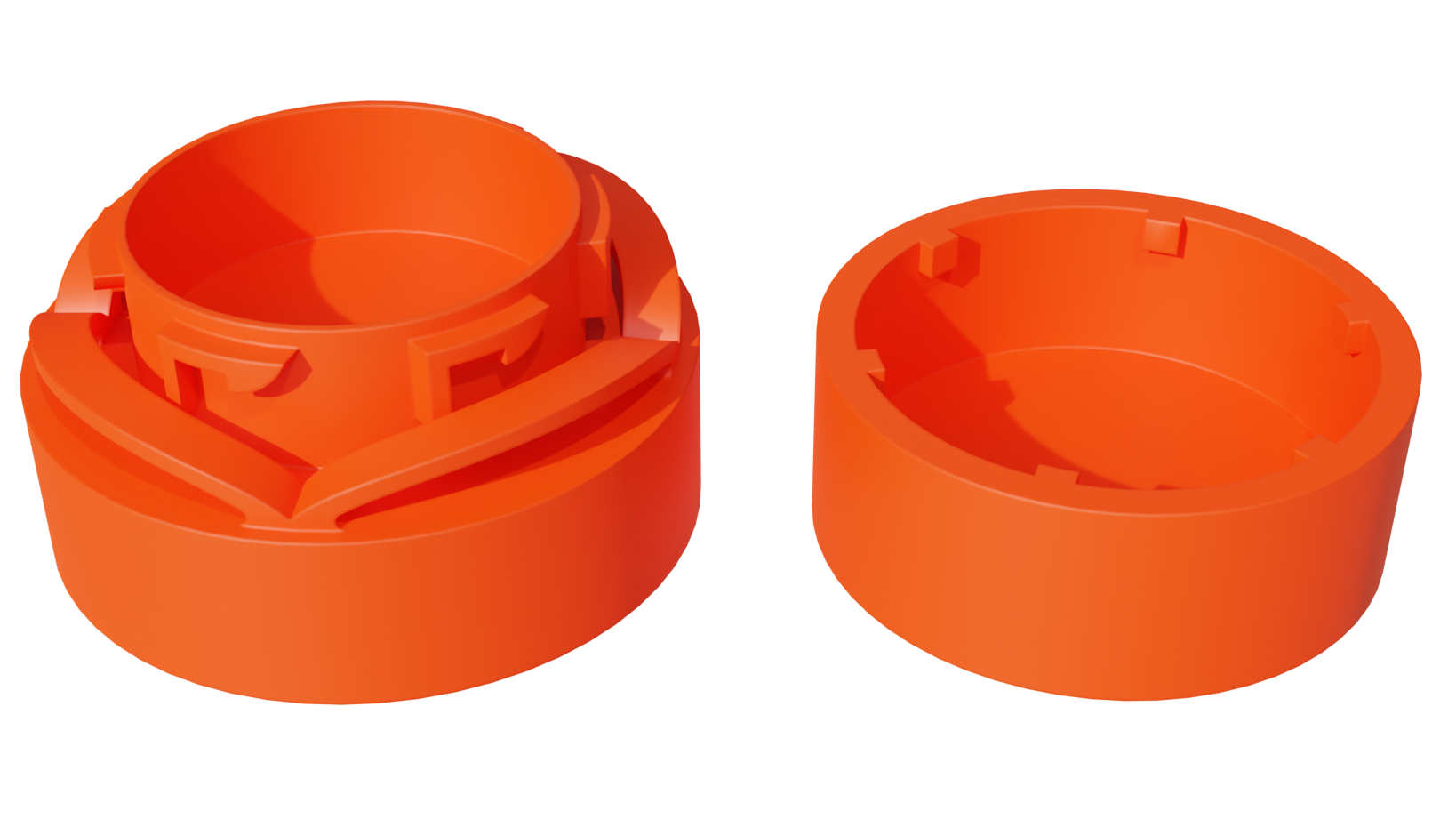

Initially, the plan was to create a rig that would hold a pill bottle on its side. However, we quickly abandoned this idea after realizing how challenging it would be for our current system to manipulate such a delicate component. Additionally, we realized we could significantly reduce the number of parts by designing our own push-and-twist mechanism.

I performed a breakdown of the pill bottle and discovered that it could be broken down into three parts. A cap, a bottle, and a spring. The most crucial component of any pill bottle mechanism is the internal spring that pushes the cap out. The pill bottles we used had an injection-molded disk with a concentric 'fold' that served as the spring. Initially, I planned to incorporate the injection-molded spring into our own design, but once we decided to increase the size of the part, I had to abandon this idea.

I planned to 3D print our solution, and so I did not believe the injection-molded design would be viable. Because of how the part would have to be printed, I felt it would be impracticle to design and would likely fail. Additionally, I felt like it would be easier to just have two parts, a cap and a bottle, with the spring built in to one of the halves. So instead, I created these arched springs embedded in the bottle to push the cap out.

Sketches & Iterations

Copyright © 2024 Siddharth Bhargav. All rights reserved.